We are committed to produce our solar cells to the highest operational standards, minimising the environmental impact of our manufacturing processes and products. Our perovskite component uses raw materials that won’t deplete the earth.

Our perovskite technology will help accelerate the deployment of solar energy to meet the ambitious targets needed to tackle the climate crisis.

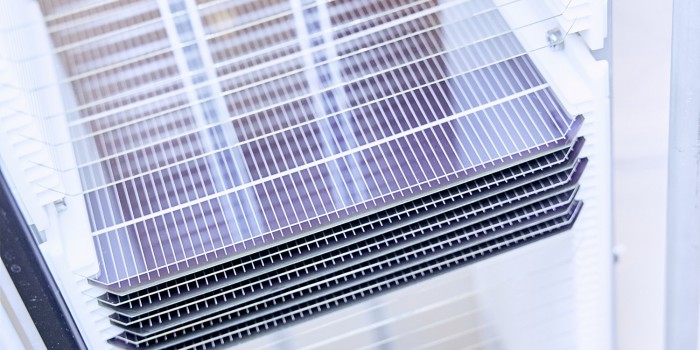

Our material can be manufactured using existing processes, making perovskite ideal for use as a partner with conventional silicon technology.

Our perovskite technology uses raw materials that are abundant and won’t deplete the earth.

The shift to a clean energy system is driving a huge increase in the requirements for critical minerals. Our perovskite technology will power solar photovoltaics at the terawatt scale using abundant and available materials, and we do not source from conflict regions.

The manufacture of solar panels and their components must respect and uphold human rights. We do not tolerate violations of ethics and dignity. We strongly condemn the use of forced labour anywhere in the PV supply chain (read our statement on forced labour).

Together, with our suppliers, we are working towards achieving the transparency, accountability, and human rights standards we require. We are travelling the journey to responsible sourcing with other members of the solar technology supply chain to make sure perovskite is a sustainable PV option.

Solar PV already has much lower lifecycle emissions compared with fossil fuels. Currently the majority of greenhouse gas emissions from PV installations come from materials extraction/processing and module manufacturing. While we do not produce modules, we want to help further reduce the carbon footprint of the wider solar industry by working with module manufacturers who share our sustainability commitment and who produce and supply locally to where their modules will be installed.

We want our product to be highly sustainable throughout its lifecycle.

Our technology is highly resource-efficient. Adding an equivalent of 0.5% by weight of our perovskite material onto a conventional silicon PV cell would enable a solar module to produce 20%–50% more power over its lifetime. This higher power output also offsets the carbon footprint embodied in the production of solar cells.

Through independent analyses, we continue to conduct lifecycle studies on solar modules containing our PV cells. Results have shown that perovskite-on-silicon modules have 6% to 18% less environmental impact than a silicon module when the additional energy generated over the tandem module’s 25-year lifetime is considered (link).

Solar modules with our product can be recycled at their end of life using the existing technology for current silicon PV modules. We are also working with companies to develop high-value recycling methodologies and circularity approaches for solar modules containing Oxford PV solar cells.

We integrate environmental considerations into every aspect of our business processes and operations. Our factory in Brandenburg is certified according to the ISO standards for energy management (ISO 50001), environmental management (ISO 14001), and quality management (ISO 9001). (View our ISO certifications here.)